Ink formulation

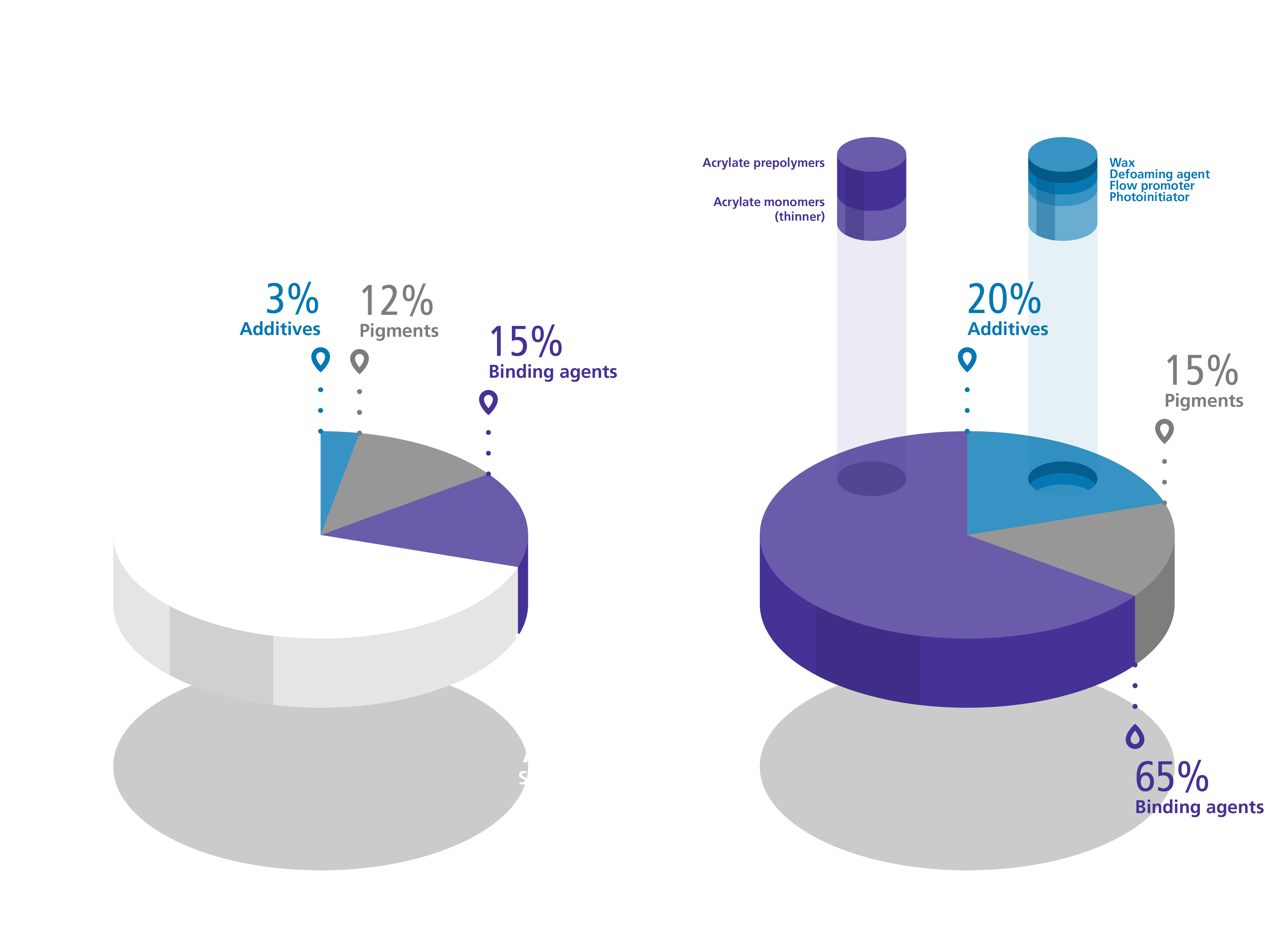

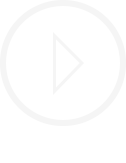

There are various types of inks, among these water-based, solvent-based, UV as well as digital inks. In principle, all types of printing inks contain similar components – but depending on print method the type of raw material and the quantity are different. Inks are formulated using four main components: pigments, binders, solvents and additives. Pigments are used to create color impressions and optical effects. Binders keep the pigments evenly dispersed and bind them to the surface of the substrate. Solvents increase the flow characteristics and viscosity of the ink to ensure processability according to the variety of printing technologies and conditions. Lastly, additives alter the ink’s physical properties to suit different situations, e.g. enhancing the flexibility of the printed film, increasing scrub resistance or promoting adhesion.

But why are there so many different ink formulations? The answer is simple: Because not every ink is suitable for every printing technology or application. Common applications, for example, include flexible packaging, narrow web, sheetfed, paper and board, tobacco, liquid food packaging or print media. And of course, reproduction of the nearly unlimited color gamut of the real world is required.

Watch our video or click through our interactive graphic to learn more about ink formulation at Siegwerk and the market segments we are operating in.

Siegwerk’s printing inks

Learn more about how our solvent-based printing inks are manufactured.

UV printing inks

All types of printing inks consist of rather similar components, however, the type of raw material and the quantity are different depending on the particular print method. The following chart illustrates the conventional composition of a printing ink – pigments, binders, solvents and additives – compared to the composition of a UV printing ink.