Siegwerk Brand Owner Collaboration

Naturally consumers demand and require safe products and they put their trust in brand owners to deliver. Thus, it is a key obligation for brand owners to fulfill these expectations by providing safe products to the market, first of all to protect consumer health and second to maintain and further extend the trust that is given to brand owners by their customers.

Siegwerk is a reliable partner for the packaging industry and committed to maximum product safety. We foster the direct exchange with brand owners to understand the product requirements in order to provide safe customized inks.

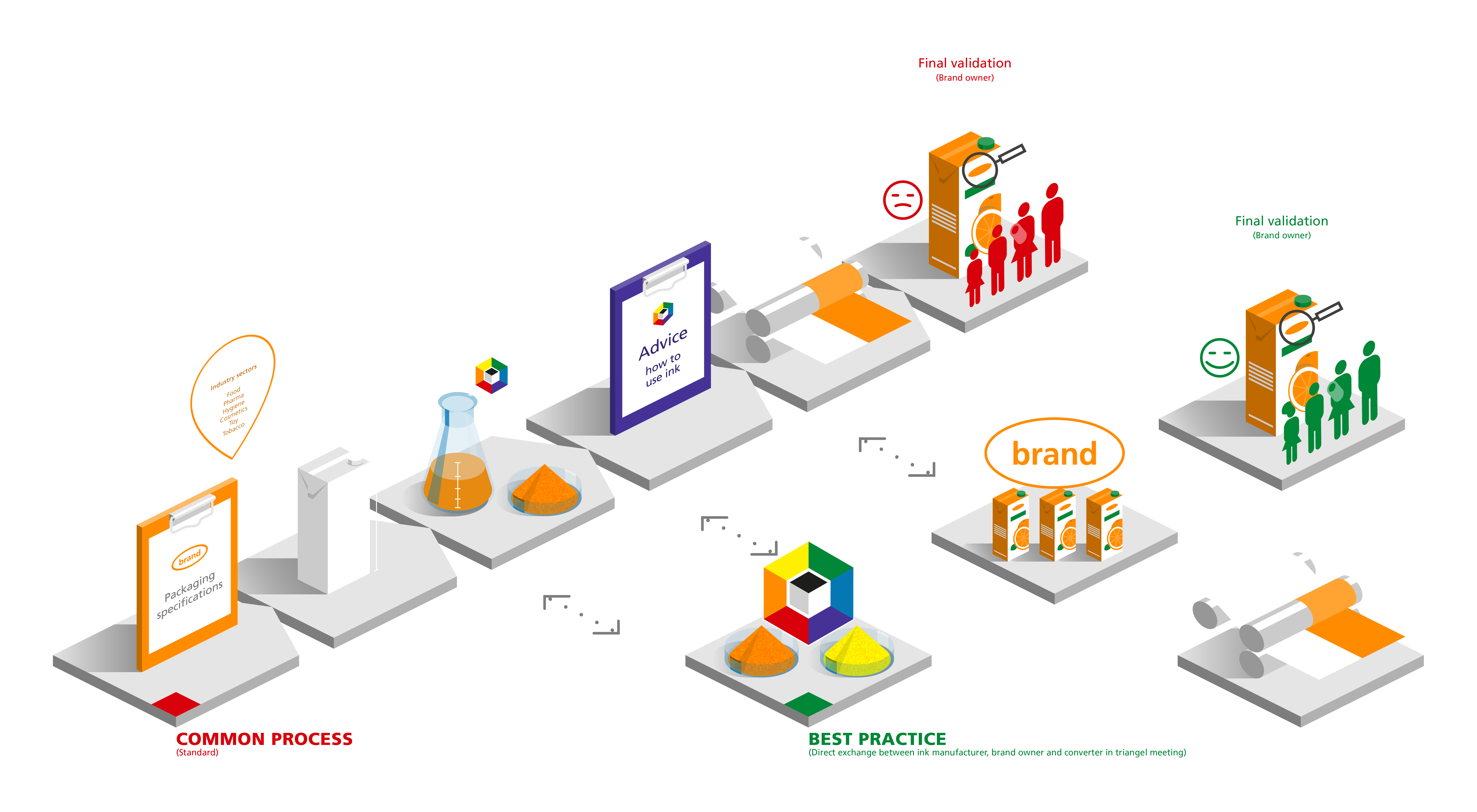

Importance of direct exchange between ink manufacturer and brand owner

In this slideshow, we introduce the importance of a direct exchange between brand owner and ink manufacturer and provide a best practice showcase to outline why the direct collaboration between the brand owner and ink manufacturer is essential to achieve a maximum level of safety for packaging solutions regarding inks and coatings.

Related topics that might interest you

For further information on food packaging regulation processes, please also check out our articles on the topics “Converter: Responsibilities within the Supply Chain“ and “The 6 Steps and Responsibilities for Safe Food Packaging“.