Responsibilities of the Converter

By providing Technical Data Sheets including detailed information on properties of individual inks and further input, Siegwerk helps converters for food packaging to align with the most advanced benchmark standards in Good Manufacturing Practices for food packaging.

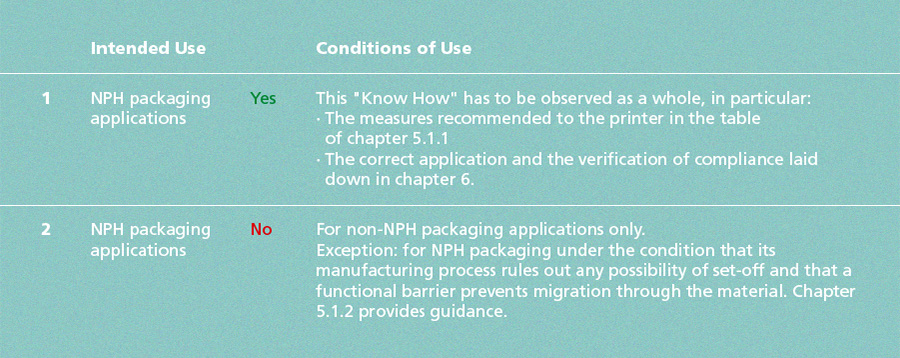

Siegwerk’s Technical Data Sheets and related communication provide data on the intended use, such as substrates to be printed on, conversion process and application conditions. With regard to the safety of the food packaging for the consumer, they further specify the intended use: either "Food Packaging: "NPH (Nutrition, Pharma and Hygiene) packaging applications: Yes" or "No". Siegwerk advises customers to follow the associated conditions of use:

Know-How brochure: chapter 5.1.1 & chapter 5.1.2 | chapter 6

Furthermore, Siegwerk provides information on the resistance and fastness properties of each individual ink. They have to be checked for applications which involve unintended but foreseeable short-term and/or low-area direct contact with food, as per chapter 5.2.1. With this information and with the following tables, Siegwerk makes it easy for the printer to align with the most advanced benchmark standards in Good Manufacturing Practices for food packaging, which specify that the converter is required to assess the migration potential of packaging inks case by case. In particular, printers worldwide are advised to align with the above-mentioned “Explanatory Note on the assessment of migration potential from food packaging inks and its dependency on the packaging structure” of PIJITF.