Practical guidelines on the application of migration modeling

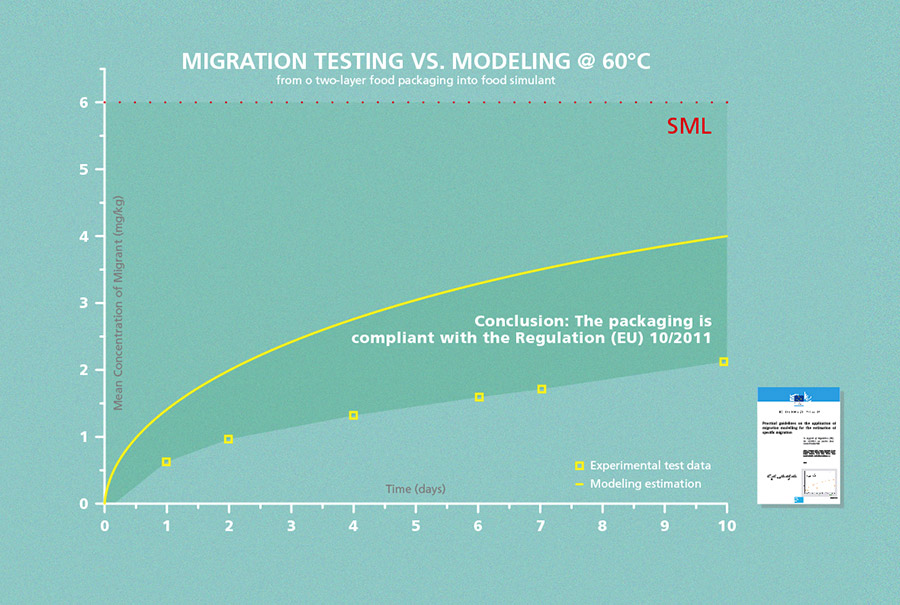

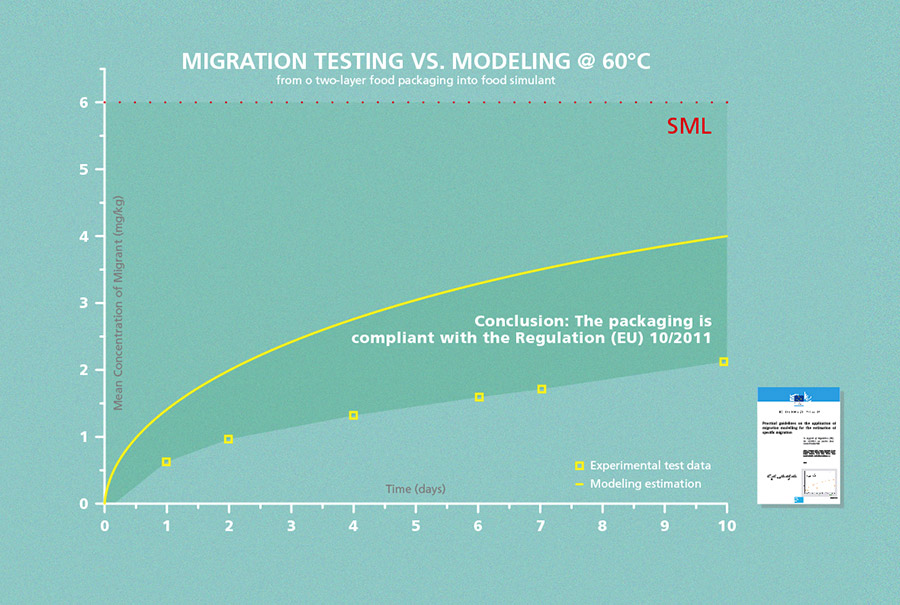

The European legislation requires verification of compliance for migration of substances from plastic food contact materials with existing specific and overall migration limits. To do so, there are migration tests to carry out using food/food simulants under the test conditions specified in Regulation (EU) No 10/2011. Numerous scientific investigations during the last two decades have demonstrated that migration from food contact materials into food and food simulants follow predictable physical processes. In the absence of specific interactions with food, migration is a mass transfer of substances from a plastic material into foodstuffs, and adheres in most cases to Fick´s laws of diffusion.

(E.J. Hoekstra, R. Brandsch, C. Dequatre, P. Mercea, M.R. Milana, A. Störmer, X. Trier, O. Vitrac A. Schäfer and C. Simoneau; Practical guidelines on the application of migration modeling for the estimation of specific migration; EUR 27529 EN; doi:10.2788/04517)

Regulation (EU) No 10/2011

“At each stage of manufacture, supporting documentation, substantiating the declaration of compliance, should be kept available for the enforcement authorities. Such demonstration of compliance may be based on migration testing. As migration testing is complex, costly and time consuming it should be admissible that compliance can be demonstrated also by calculations, including modeling, other analysis, and scientific evidence or reasoning if these render results which are at least as severe as the migration testing. Test results should be regarded as valid as long as formulations and processing conditions remain constant as part of a quality assurance system.”

(COMMISSION REGULATION (EU) No 10/2011)

European Printing Ink Association (EuPIA)

“The printer should conduct representative practical investigations, such as migration testing or migration modeling, to cover each relevant packaging application category and structure. If required, EuPIA members can help identify suitable laboratories that have the required analytical capability to give a qualified verification of compliance of printed packaging.”

(EuPIA, Frequently Asked Questions on the Legal Status of Printing Inks, Coatings and Varnishes for the Non-food Contact Surface of Food Packaging)