Worst case calculation

In the absence of specific EU legislation for food packaging inks, the European Printing Ink Association (EuPIA) has developed a guideline on migration test methods for the evaluation of substances in printing inks and varnishes for Food Contact Materials. Accordingly, data on migration should be obtained either by experimental testing in accordance with EU legislation (Commission Regulation (EU) No 10/2011 on plastic materials and articles intended to come into contact with food) or by other alternative scientific tools such as worst case calculation. Such calculations are explicitly allowed in the aforementioned EU legislation on food contact materials and are deemed suitable for compliance assessment.

Printing inks for indirect food contact applications have not been specifically regulated in the USA yet. Nevertheless, a worst case calculation for migrants is done based on parameters approved by the FDA in official pre-notification consultations with Siegwerk (PNC 2473, 2489 and 2564).

For further information on how to use the worst case calculator, please download the attached PDF-document.

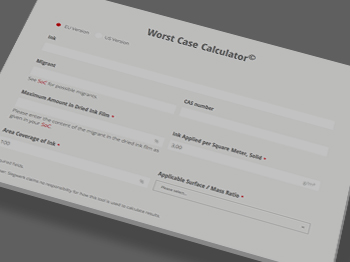

Worst Case Calculator©

Disclaimer: Siegwerk claims no responsibility for how this tool is used to calculate results.Summary

Assumption of 100% migration

With our Worst Case Calculator©, the recipient of a Statement of Composition (SoC) is able to easily determine the maximum amount of a migratable substance that could, under worst case conditions, end up in the packed food. Here, the underlying principle is the assumption of 100% migration of the substance, which always leads to an overestimation of the calculated result compared to real migration values. Variables that can be inserted into our worst case calculation include the migrant name and chemical identifier (CAS No., information provided with SoC), the content of migrant in solid ink film (information provided with SoC), the dry ink applied per square meter, the area coverage of ink and the surface-to-mass ratio (EU-cube or real surface/mass ratio).

Important parameter: Surface-to-mass-ratio

A higher amount of applied ink, as well as a higher surface coverage will always lead to increased migration values. Next to these parameters, the surface-to-mass ratio for the packaging material has to be considered as it is a crucial parameter. An increase in the surface-to-mass-ratio leads to increased migration results, thereby the chance of exceeding the specific migration limit (SML) is more likely.

Exposure assessment

If the results of the worst case calculation (tier 1 within Siegwerk’s exposure assessment) for the packed food unit are lower than the applicable thresholds, no further measures are required. Otherwise, further refinement such as migration modeling (tier 2) or migration testing (tier 3) are necessary.

Worst Case Calculator© Non Finished Inks

For “semi-finished inks/varnishes”, we can provide our Worst Case Calculator© Non Finished Inks. You can use this to carry out a Worst Case Calculation for an ink or varnish, which the converter produces from two or more “semi-finished inks/varnishes” supplied by Siegwerk.